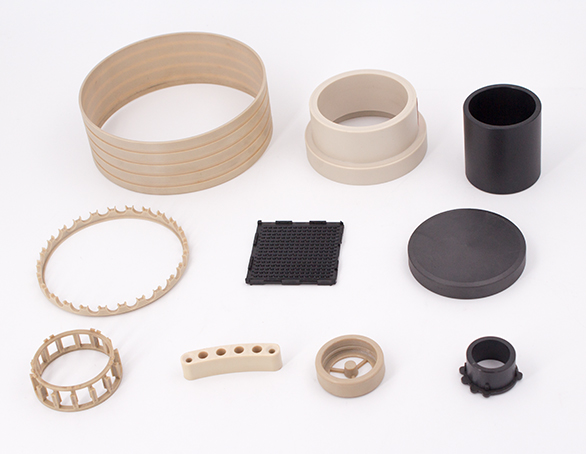

PEEK material can be used in a variety of precision machinery parts, such as automotive gears, oil screens, shift start plates, aircraft engine parts, automatic washing machine wheel, medical device parts, etc. Typical PEEK products include bearing retainers, metal bearing linings, clutch parts, vacuum parts for power brakes, pulley loader blades, copier parts, liquid chromatograph filler crowns and connecting microtubes.

The use of its heat resistance and chemical resistance of good advantages for the manufacture of hot water, chemical pump body and impeller and other parts, steam gas valves, O-ring, boiler with pH meter sheath, microscope lampcover, motor surrounding wire bracket, rocket battery slot, bolts, nuts, laboratory tweezers, etc. PEEK material is commonly used to make axle sleeve, bearing, roller and amplitude adjusting nut of textile and packaging machinery, compressor valve disc, piston ring, seals and various chemical pump body, valve parts, wherein material selection is extremely important in today's rapidly developing and competitive textile market.

Mechanical speed, flexibility and reduced downtime are critical factors to meet the growing market demand for rapid production of high quality textile products. Moreover, PEEK polymer material has good function at high temperature and excellent chemical corrosion resistance, hydrolysis resistance and wear resistance, so it is a good material for extending parts life and reducing machine operation cost in textile machinery.